what’s Instrumentation and control automation

Instrumentation and Control is the part of

engineering that is concerned with measuring and controlling processes. To get the proper final product from the different industrial processes, a series of measurements and controls are needed. So, instrumentation in the UAE is very important for controlling and keeping some variables the same in these processes.

Instrumentation and control are a large field with two branches that have been joined together to make a new branch.

Instrumentation engineering is a field that focuses on how

measuring instruments work and how they work in general. This is important for designing and setting up

automation systems. The automation system can be used in electrical,

pneumatic, or other fields as per demand and use case.

It is a field of study that brings together different subfields. Control systems, automation,

electronics, and information technology are some of these.

Instrumentation in the UAE is about measuring the different parts of the process (PV). Pressure, flow, level, temperature, pH, conductivity, speed, humidity, etc. are all examples of process variables.

Instrumentation is defined by the Instrumentation and Systems Automation Society (ISA) as per Reference: ISA standard S 51.1 is a list of instruments and how they should be used for observing, measuring, and controlling.

Control is a field that looks at automation and the making of systems that control processes.

Why is it important to have instruments?

It is now possible to make complex products in a way that retains their quality and uniformity over time and with fixed characteristics. Without measurements, it would be either impossible or very hard for the operator to manually control the process.

Instrumentation is the ability of a person to measure and control processes and the environment. It is part of a control system.

So, Instrumentation's main job is to ensure

- Pressure, temperature, and other physical parameters are measured

- physical parameters that are not vanity

- Data is put into control loops so that the physical values at the site are controlled

Measurement and control

The measuring tools are the most important part because they make it possible to control different process variables in ideal conditions. Measurement can be thought of as a group of components that come together to make an instrument. It turns a physical variable into an easy-to-understand signal or indication.

Instrumentation in the UAE is governed by international standards like ISA, API, IEC, NEC, and ANSI. These standards control how measurements are made and how processes are controlled. International standards make sure that different things are within the stipulated standards.

Automation

In automation processes, industrial instrumentation is very important. It can keep a whole industrial system under control and monitor it. Automation in a plant ensures accuracy and efficiency while using the fewest number of people. Also, it can set quality standards and get results.

A short explanation of what industrial instrumentation is.

An industrial instrumentation company is needed for industrial processes, especially those that are meant to be automated. It is a group of things that help make sure that industrial processes and how companies handle their resources work well and get better.

Industrial instrumentation takes into account different factors and measures, converts, and keeps track of them to make sure processes work. For this protocol to work, engineers in the area have to use special tools and devices.

As a starting point, there is the measurement and control of processes that usually measure physical factors like:

- Pressure and force

- Levels and flows

- Temperature

- Speeds and weight

- Dew point and humidity

- Chemical properties, such as pH and electrical conductivity.

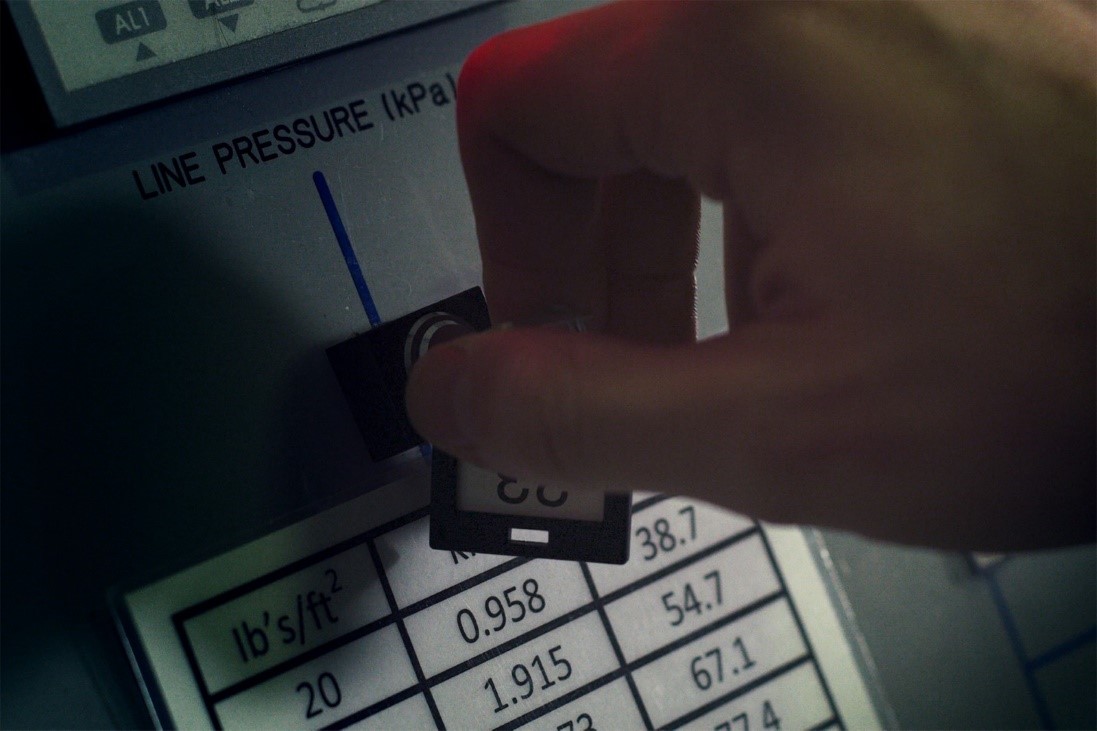

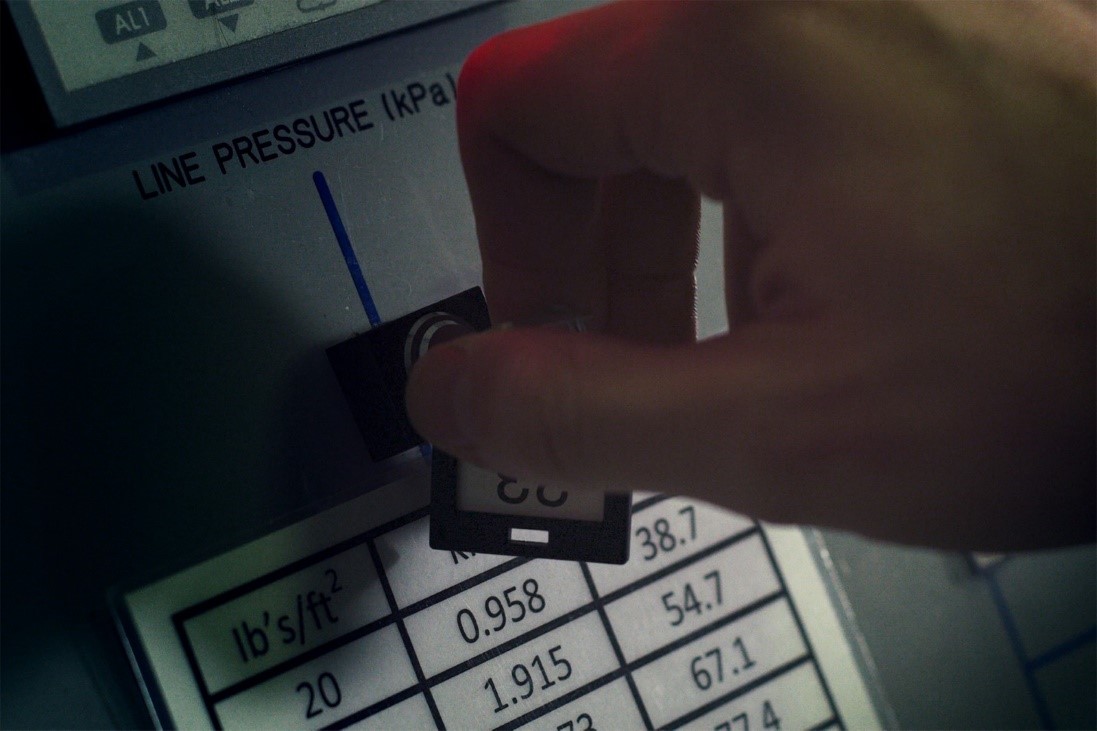

The output of the transmitter can be seen through built-in local indicators, which are also collected in the control room. The signal is sent to the DCS, PLC, or

SCADA systems, which then do more work with it. In the human-machine interface, we can see how measurements are shown and how loops are controlled (HMI). From the same HMI panel, it is possible to look at alarms and acknowledge them.

Real-time industrial instrumentation has these traits

The architecture of industrial instrumentation determines what it can do in real-time applications and how it works. In short, instrumentation in the UAE system is made up of

sensors, transducers, input devices, controllers, processors, transmitters, actuators, or output devices.

The physical value is turned into an electrical signal by the sensor. For example, RTD turns temperature into voltage so that PLC and SCADA systems can use it and show it.

The transmitter changes the electrical signal, which is usually a voltage, into a current signal of 4-20 mA so that it can be sent over a long distance.

If you need to, you can control the instrument directly. Most of the time, the signal goes to a PLC.DCS, SCADA system, or other controllers. The system figures out what the data means and shows the information to the operator. It also controls the process at the same time.

Sensors are one of the most important parts of industrial instrumentation, which has a lot of different parts. It is the process of turning what a sensor sees into a signal that can be sent out.

This function is very important in automation because the signals that are received are turned into optical, electrical, mechanical, etc. Signals.

Instrumentation and Control

How important industrial instrumentation depends on how well the equipment is taken care of, how resources are used, the tools used for work, safety rules, the environment, etc.

Making sure the devices used are of good quality is important if you want smart and effective work processes. Instrumentation companies in UAE guarantee competitiveness, good production results, and savings on costs.

Today's business world is especially affected by how important industrial instrumentation is. Most helped businesses are

- The oil and gas industry

- Pharmaceuticals

- Power generation

- Chemicals, Pulp & paper

- The automotive industry

- Construction and cementing

- Food and drink industry and textile industry

What an Instrumentation Engineer Has to Do

The Instrumentation companies in UAE and

Control Engineer is a professional with the training and skills to create, manage, and give advice on projects and assemblies that automate industrial processes. Fixing problems with automation, using and improving the systems that are already in the plant.

The engineer in charge of instrumentation and process control helps make the technical specification sheets for the instruments. The control loops and the control architecture will be on the specification sheets. We use it to look over the plans for the pipes and instruments. Also, for making the control logic, which can be

electronic, pneumatic, or

hydraulic.

Designing, making, evaluating, revising, analyzing, or changing the following documents

.

- Instrument List, P&IDs,

- Instrument diagrams, Instrument datasheets,

- Technical specifications, Wiring diagrams,

- Requests for price quotes, to buy,

- Calculations,

- Schedules for both preventing and predicting,

- Plan for calibration, List of spare parts,

Instrumentation Engineer Responsibilities

The maintenance technician's job can involve more specialization in areas like instrumentation and control, process knowledge, and mechanical and electrical skills. Helped mechanics with installing new equipment, making changes, calibrating equipment, inspecting, running routine tests, and figuring out what was wrong with certain machines. Depending on the size and type of an organization, the duties can be different.

Tasks for preventive maintenances, fixing problems when they happen, and corrective maintenance based on

maintenance protocols. Part of the job is also to keep track of different records.

Safety Control and Instrumentation in UAE

In every part of day-to-day

plant maintenance, it is of the utmost importance. Paying attention to safety is important for both the people working in the field and the equipment they use.

Instrumentation and control have a lot of benefits

Instrumentation and control are helpful in the process industries in several ways.

- Productivity has gotten a lot better.

- Enhances the market's competitiveness

- Optimizing the flow of data.

- The safety of the workers is improved, especially when there is a dangerous, explosive atmosphere, temperature, or weight.

Service for Instrumentation in UAE

Service life cycle management is one of the most important things to think about when buying equipment. No matter what industry you are in—

pharma, biopharma, university, or food and beverage—proper life cycle management starts with the right installation of the equipment and basic user training. This is followed by routine preventive maintenance visits. These services will make the unit last longer, cut down on downtime, and limit product loss.

Instrumentation companies in the UAE serve customers all over the world. They offer service contracts and a full range of services and training courses that are just right for every need. They will work with you to find the best way to fix your system, instrument, or another piece of equipment. So that you can protect the quality of your results through the manufacturing process.

Help from professionals when you need it

In the unlikely event that an instrument breaks down, their team is ready to help with technical advice and help. They make it easy for you to get original replacement parts quickly if you need them.

You can talk to them if you have questions about the services they offer or if you need technical help.

Bundle of White Paper on Metrology

With its series of white papers, which will eventually be put together into a Best Practice Guide: Lab Weighing, instrumentation companies in UAE give practical answers to the most important questions and issues about weighing in the lab.

Instructions on how to test laboratory scales regularly

In most labs, weighing is a very important step. Lab balances need to be maintained and calibrated regularly to give results that can be trusted and repeated. Routine testing is just as important as professional services. Sartorius gives useful information on the most important and useful routine tests through a set of Generic Operating Procedures.