A guide for tubes and tube fittings in the UAE

Tube fittings in Dubai join tubing runs (in in-line, offset, multi-port, and mounting designs) to other tubing sections,

pipe,

hose, or other components. Typically, systems consist of straight parts joined by fittings

Or specifically constructed joints and connections.45 Degree Male Elbow Fitting picture

Tubing vs. Piping and Hose

Initially, it may be necessary to separate some terms. In the business world, "tube" and "pipe" are practically synonymous. Both terms refer to lengthy hollow cylinders of homogenous material that are hard and permanent. In contrast, a "hose" is often more portable and flexible and is composed of numerous layers of various materials that change depending on the use.

The distinction between tubes and pipes lies in their respective specifications. Typically, tubes and fittings in Dubai are characterized by their precise dimensions rather than their nominal ones. In other words, the outer diameter of a tube with a 1.5" OD rating will typically measure precisely 1.5 inches. Not so with pipelines, where real dimensions often differ from nominal (specified) specifications.

In addition, tubes are often related with structural applications where the outer diameter is the defining dimension (OD). Inside diameter is the most common size parameter for pipes, which are often containers for transporting fluids (ID).

Applications

Construction and material requirements of fittings are application-dependent; it is often prudent to contact the fitting manufacturer to optimize component choices. Nevertheless, the majority of tube fittings near Dubai correspond to

hydraulic or

pneumatic systems. Step one in selecting the proper fittings for a given application is to identify the fundamental system type.

- In hydraulic applications, liquid fluids such as water and other chemical solvents are transferred. Seals on hydraulic fittings must prevent liquid leakage and often be resistant to rust and other forms of chemical damage.

- In pneumatic applications, gases are transferred. To avoid gas loss, pneumatic fittings must have very tight seals and be resistant to chemical damage.

- Other applications, such as structural design, use tube and tube fittings in the UAE as well. The physical integrity of these fittings must be robust, but they normally do not need sealing since they do not transport fluids.

Types of Fittings

The difference between tube fittings is based on their connection types and their purposes.

Connection

Various connection techniques are used to attach fittings to tubes in the UAE, each with its own benefits and conveniences.

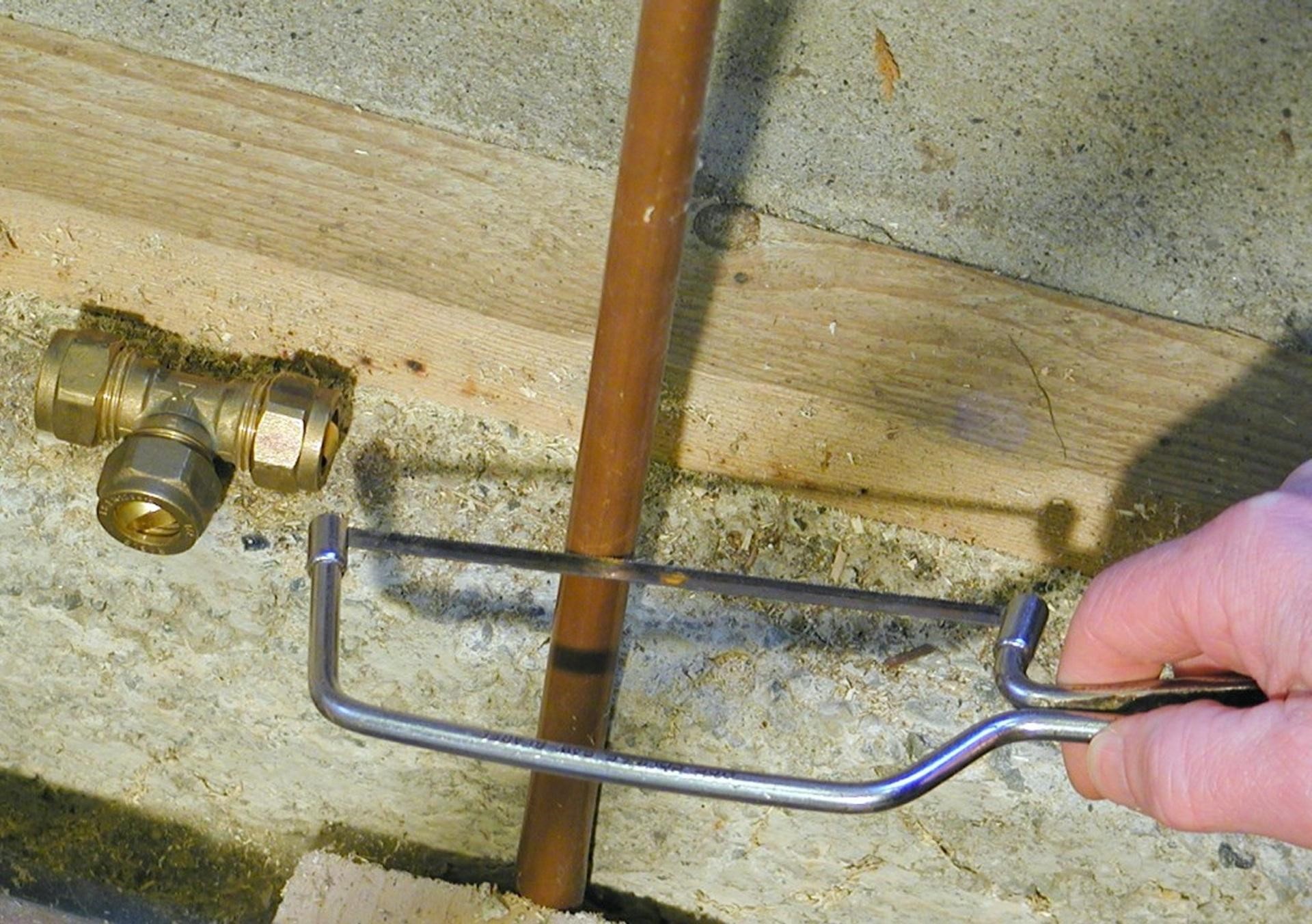

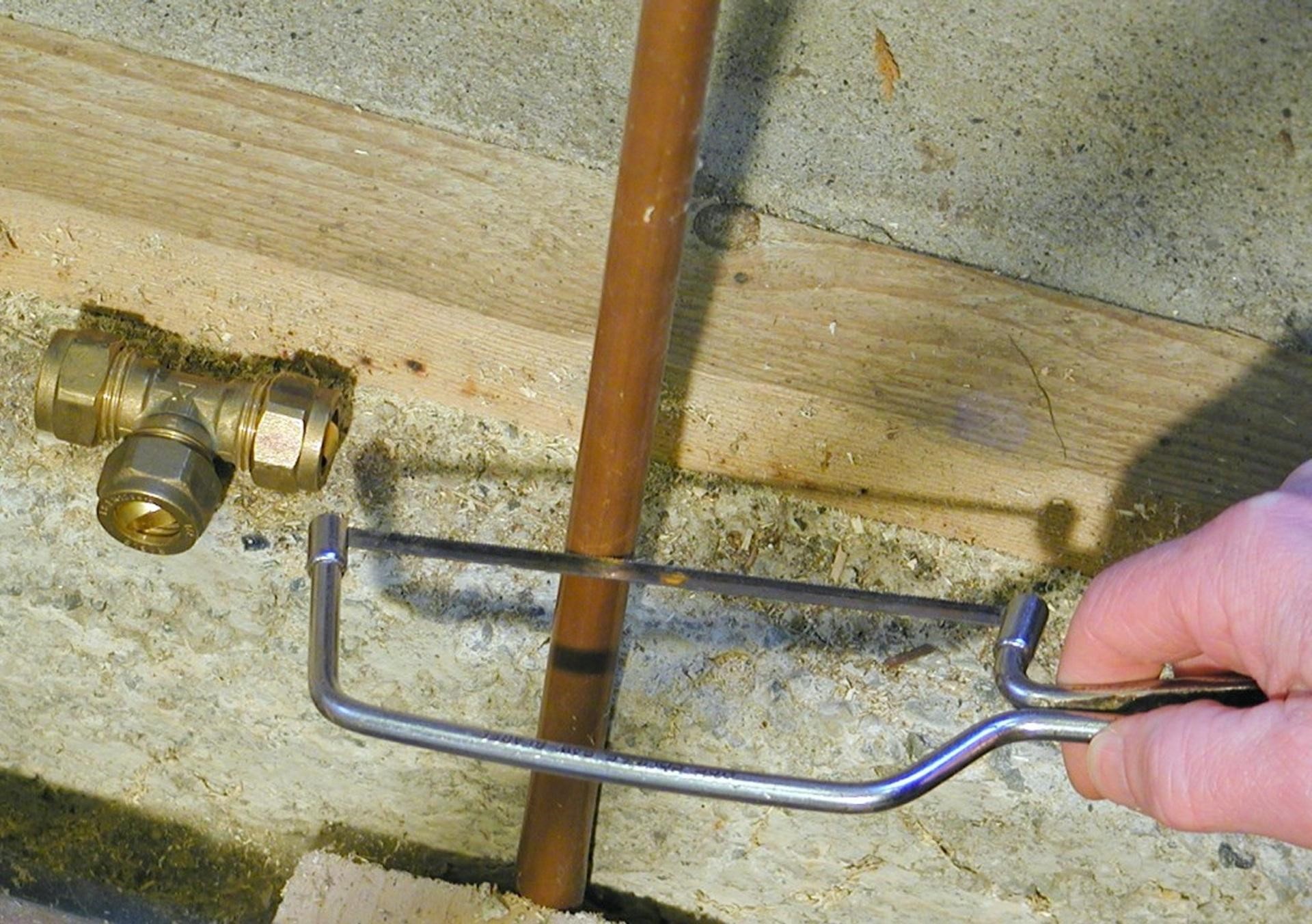

Compression fittings

Compression fittings are used to join tubes in the UAE by applying pressure on a

gasket, ring, or ferrule. Typically, compression is achieved by tightening a nut on the fitting over the tube and ferrule, compressing and securing the tube inside. Standard compression fittings may be assembled without the need of tools, allowing for rapid and easy installation. However, they cannot tolerate extremely high pressures and lack the flexibility of soldered fittings, rendering them less useful in systems subject to vibration, heat cycling, and other dynamic forces. Additionally, they are available in a limited number of materials (brass being the most popular) and are best suited for metal-to-metal connections.

Bite-type fittings

Bite-type fittings are compressive fittings with a pointed ferrule that "bites" and seals the tube when squeezed. Bite-type fittings, like ordinary compressive fittings, do not need any special equipment for assembly, but they provide a stronger, higher-pressure connection.

Mechanical grip fittings

Mechanical grip fittings consist of a pair of ferrules. The rear ferrule grabs the tubing while pushing against the front ferrule, creating a seal between the tubing and fitting body. These fittings may be disassembled and rebuilt several times without causing damage to components or tubing. They have excellent mechanical vibration resistance.

Flare fittings

Flare fittings have bodies with flared or coned ends. Special flaring

tools are required to attach the tube so that it fits snugly into the flared end and creates a tight seal. Standard compression fittings can only withstand greater pressures and a narrower range of operating conditions than flare fittings.

End fittings

End fittings offer particular connection surfaces for tubes fitting near Dubai.

- Clamp ends are fittings that provide clamping of tubes to a connector.

- Plain ends are fittings that let tubes be joined through glue, solder, or other methods.

Flange fittings

Flange fittings are ports with smooth, perpendicular surfaces to the connecting tube. Using clamps,

bolts, and/or welding, these surfaces are linked and sealed. Visit the Pipe Flanges Selection Guide on IEEE Global Spec for further information on flanges.

Luer locks

Luer locks are sleeve fittings that provide simple, effective connections (often for one-time use) by a rapid twisting movement. It is most often used in medical and laboratory settings.

Push-to-connect or fast coupler fittings

The ends of push-to-connect or fast coupler fittings are intended to receive tubing by pushing it in. Typically, these fittings detach through some form of collar retraction. Sections of the system needing frequent separation and reconnecting benefit from quick connections.

Threaded fittings

On the inner (female) or outer (male) surfaces of threaded fittings are screw threads (grooves) intended to accommodate tubing with matching threads. Straight threads are those that give a straightforward connection but no seal. Tapered threads are intended to create a tight seal for pressurized gases or fluids. Adding a coating or seal tape may increase the seal's dependability (Teflon). The term "dry fit" refers to threads that seal without the need for extra sealant, which is crucial in situations where sealant addition might lead to contamination or corrosion.

Function

There are several kinds of fittings fitted in tube systems that serve various purposes. The majority of fittings fall into one of four categories:

Fittings for extending or capping tube lengths:

Adapter

Uses solvent welding, soldering, or threading to affix two different tubes together.

Coupling

Utilizes solvent welding, soldering, or threading to attach two comparable tubes together.

Sleeve

Using mechanical fasteners, connect two tubes (e.g., screws, anchors). Installation is often faster and less complicated than soldered or welded couplings.

Union

Connectors that can be separated without cutting. Their (usually threaded) connection enables for simple release.

Cap

Covers the end of a tube, connecting through welded or threaded connection to the male end.

Plug

Attaches through welded or threaded connection to the female end of a tube to seal it off.

Accessories that add or modify direction:

Elbow

Modifies the tubing's orientation to different angles. The most frequent angles are 90 and 45 degrees, although 22.5-degree elbows are also manufactured.

Tee

Creates a T-shaped connection between three tube segments. This enables the combination or separation of fluid flow.

Wye

Connects three tube segments at a Y-shaped juncture. They are similar to tees in that they combine or divide fluid flow, but with less resistance.

Cross

Four-way connectors that provide one input and three outlets, or vice versa. Crosses are less stable than tees, and temperature variations may cause considerable stress on the tube in Dubai.

Connecting components for smaller tubes in the UAE:

Reducer

Includes all connections between two or more tubes of varying diameters

Olet

When no suitable reducing tees or crosses are available, a reduction fitting is fitted to branching connections.

Nipple

Permits connecting two distinct fittings at either end. Standard nipples have male threads on both ends and are straight.

Barb

A barbed tube in the UAE with a tapered stub and ridges is put into the hose that connects the tube to a flexible hose.

Valve

Connects tubes in the UAE with the addition of a control

valve for flow regulation. Visit the Industrial Valves Selection Guide on Engineering360 for additional details on various kinds of valves.

Specifications

Sizing

After determining the kind of fitting needed, the most basic component of tubes and tube fittings in the UAE may be addressed: size. Oversized or undersized components will either be wholly incompatible or will seal or join improperly, making accurate sizing a must for effective fitting choices.

Depending on the method of measurement, fitting sizes are commonly expressed in millimeters (mm) or inches (in). The user must pick a fitting that is sized using a system of measurement (Metric or English) that is compatible with the equipment or assembly being fitted for proper sizing.

The interior diameter (ID) and outer diameter (OD) of a fitting's associated connections, measured in inches (in) or millimeters, describe its size (mm). A fitting intended to connect to a tube with a 2" OD is classed as a 2" OD fitting. The inside diameter measures the diameter of the empty region of the cylinder, while the outer diameter includes the wall thickness.

Operation

The most critical operational criteria for fittings are pressure and temperature.

The operating pressure range is the working pressure range or the

pressure ratings at which the fitting was intended to function. It is commonly measured in pounds per square inch (psi) (psi). Operating over or below this limit may result in fitting failure (i.e., break, leak, lose its seal).

The operating temperature range, measured in degrees Fahrenheit (°F) or degrees Celsius (°C), is the working temperature range or temperature ratings at which the fitting was intended to function. Operating above or below this grade might result in failure of the fitting.

Materials

Frequently, the materials for tubes and tube fittings in the UAE are chosen concurrently with the materials for the tubing. Cost, flexibility, media, environmental circumstances, and needed pressure ratings influence the selection process. Plastics and metals are among the available material options.

Typical metals include:

- Aluminum: it is lightweight and resistant to corrosion. Aluminum is extensively used in plumbing and is the material of choice for aluminum tubes and tube fittings in UAE. Aluminum has a low tensile strength and is used when corrosion resistance is essential. To increase its strength and hardness, it is alloyed with zinc, copper, silicon, manganese, or other metals.

- Brass: it is sturdy, resistant to corrosion, ductile at high temperatures, and an excellent conductor. Brass, a copper-zinc alloy, is the most used tubes and tube fittings in the UAE material in industry because of its machinability and superior performance characteristics. Brass fittings may have a variety of protective or ornamental coatings that should match the tubing's finish.

- Cast iron: it is durable and resistant to abrasion. Due to its resistance to abrasive materials such as sand, gravel, solid wastes, and debris, cast iron tubes and tube fittings in the UAE are typically employed in building construction for sanitary, storm drain, waste, and vent tubing applications.

- Copper: it is very resistant to corrosion and has great conductivity. Copper fittings are essential for a variety of plumbing and heating applications, and they are often used for domestic water supply lines. Copper fittings are often used with copper tubing and are available in either soft or stiff versions. Copper that is soft or ductile may be readily shaped and bent, and is the only material suited for flare connections. Unbendable copper needs directed fittings to go around curves and obstructions.

- Steel: it is durable, sturdy, and has great heat resistance. Steel is an iron-carbon alloy that is often alloyed with other metals to increase its corrosion resistance and durability. Water, combustible gases, and other fluids are transported through it in commercial and industrial uses. The zinc coating on galvanized steel provides rust and chemical corrosion resistance. Carbon steel is alloyed with increasing amounts of carbon to enhance its durability and strength.

- Stainless steel: it is reasonably durable and resistant to chemicals and corrosion. Stainless steel is a steel alloy containing more than 10.5% chromium, which provides good corrosion resistance for hygienic applications and those involving abrasive fluids and chemicals.

Common plastics consist of:

PVC (polyvinyl chloride): it is the most often used material for tube fittings near Dubai. PVC is a hard plastic that is available in several pressure ratings. Connecting fittings with threads or solvent welding (glue). Standard uses include the delivery of cold water and drainage.

ABS (acrylonitrile butadiene styrene): it is a black, stiff plastic with comparable qualities and uses to PVC, but is often less expensive.

Polyethylene (PE): it is the material of choice for applications involving hot and cold temperatures. PE is a semi-flexible, grey or black

plastic. Fittings are often used for sprinkler system supply lines and subsurface geothermal heating loops.

Polypropylene (PP): thermoplastic polymer with superior cold flow, bi-axial strength, and yield elongation. It is comparable to PVC, but its resilience to UV, weathering, and ozone makes it suitable for use in exposed applications.

Nylon is a chemical: and corrosion-resistant material. It is the plastic of choice for applications involving combustible liquids, chemical solvents, and drinkable water.

It is vital to determine if the system fluid is compatible with the suggested fitting materials. Corrosion may develop from incompatibility, leading to leakage or system damage.