Hydraulics Equipment 101: An Overview

Hydraulic equipment is powered by fluid and force. They function when force or pressure is applied to a fluid, resulting in the transfer of energy from one location to another. Control valves inside these systems regulate the fluid, which is commonly an oil, either manually or automatically. Through tubes and hoses, the liquid is delivered.

The

hydraulic press is the very first piece of hydraulic equipment ever created. It was invented in 1795 by Joseph Bramah, a British inventor. First used for metal forging, equipment operation,

elevator operation, canal lock operation, and bridge section rotation in England. ASME recognized Harry Franklin Vickers, an American inventor, as the "Father of Industrial Hydraulics" despite the early history of

hydraulic equipment. After more than a century, his most renowned creation was the balanced vane pump, a kind of hydraulic pump. Nevertheless, he was also the inventor of the first hydraulic power steering system. His innovations were important to mechanics, machining, and the

automobile industry.

Today, most of the equipment and systems that use hydraulics have a lot of power and are built to last. However, they are highly adaptable. Hydraulic presses, hydraulic pumps, hydraulic motors, hydraulic cylinders, and hydraulic lifts are examples of common hydraulic equipment in the UAE. A hydraulic press provides compressive forces and functions as a lever. Hydraulic pumps feed bigger hydraulic equipment with a fluid. Hydraulic motors then transform hydraulic pressure and flow into torque and spin. They provide power to a variety of devices, including mixer and agitator drives, plastic injection machines, metal shredders, cranes, and

military vehicles. Meanwhile, hydraulic cylinders provide force in a single direction. They are often found in engineering vehicles, construction equipment, and industrial machines. Hydraulic lifts are used to raise, lower, support, and transport large items or work areas.

Numerous sectors, including

material handling,

construction, roofing, masonry, automotive, aviation, and manufacturing, use modern hydraulic equipment in the UAE. In material handling, construction, roofing, and masonry, hydraulic equipment suppliers supply equipment such as lifts, bulldozers, and cranes are used. In the automobile and aviation sectors, meanwhile, hydraulic equipment is used for power transmission and brakes. Lastly, hydraulic equipment aids in the assembly and automation of industrial processes.

Hydraulic equipment needs a variety of supplies, including actuators, accumulators,

filters, tubes, and

valves. They are kept together by components like seals, connectors, and fittings. To ensure the safe and efficient operation of their systems, hydraulic companies in UAE make the equipment from materials that function well under pressure.

Rubber, woven wire,

stainless steel, cast iron, and brass are among these materials. Hydraulic equipment in the UAE uses fewer or no mechanical levers and gears, as opposed to non-hydraulic equipment that performs equivalent functions. This is another reason for their widespread usage.

Please read the sections below for further information about hydraulic equipment suppliers and

tools. They give information on several hydraulic components. To acquire one of these components, contact one of the hydraulic equipment suppliers mentioned in the respective section. These hydraulic equipment

manufacturers and suppliers are knowledgeable and trustworthy.

Hydraulic Cylinders

Mechanical actuators are hydraulic cylinders, often known as linear hydraulic motors. Their objective is to transfer hydraulic energy from pressured fluids into mechanical energy that can be used. This mechanical energy could then be used to regulate the motion of machine attachments and links.

The components of a cylinder consist of a barrel, a cap or base, a head, a piston, a piston rod, seals, and seal glands. The barrel is the cylinder's body and serves to maintain pressure. The cap encloses the pressure barrel at one end and serves as a mounting component.

Bolts, tie rods, welding, or threading are used by manufacturers to attach the cap to the barrel. In addition, an O-ring is placed between the barrel and the cap (except when the cap is welded). The other end of the barrel is enclosed by the head. It attaches to the barrel through bolts, tie rods, or threads and has a static seal.

Hydraulic cylinders are used by the aerospace, agricultural, automotive,

aviation, construction, machining, manufacturing, and military, oil and gas, robotics, and waste disposal sectors. Within these industries, they serve machines like spaceships, planes, backhoes, snowplows, brakes, cranes, dump trucks,

elevators,

bulldozers, jacks, forklifts,

lifts, power steering equipment,

material handling equipment, and robotic arms.

Hydraulic lift

Hydraulic lift systems are used for lifting, lowering, supporting, and moving large items or work surfaces. Equivalent to work surfaces they are often used in industrial and manufacturing environments, although they can also be used privately for accessibility reasons. There are several varieties of hydraulic lifts. Lift tables, scissor lifts, aerial lifts, platform lifts, vehicle lifts, and pallet lifts are some examples.

Lift tables are used to put work supplies in an ergonomically advantageous location for worker access. When raised, the base of a scissor lift is crossed and extends like an accordion, thus the name. You can develop the platform or basket atop a scissor lift till it reaches the desired height. Of course, scissors lifts can't go on forever.

- However, aerial lifts, a form of scissor lift, can often extend to whatever height is required. Generally, they can reach heights between ten and fifty feet.

- In contrast, platform lifts, commonly referred to as raised work platforms, are quite big.

- Vehicle lifts, which are used in vehicle maintenance and inspection, are among the strongest hydraulic lifts.

- Pallet lifts, sometimes known as transformers, are used to hoist pallets during cargo handling and shipping operations in warehouses.

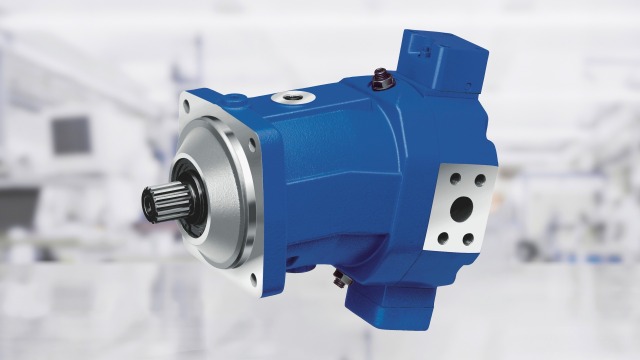

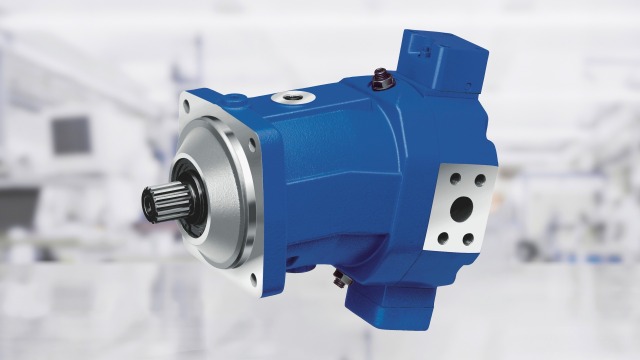

Hydraulic motors

Hydraulic motors convert hydraulic pressure into usable rotational energy for use in construction equipment, recycling operations, wheel motors, self-driven cranes, excavators, agriculture, conveyor systems, dredging, and many other industrial applications. Hydraulic motors are technically mechanical actuators since they transform pressure into rotational energy and torque. In addition, they are the rotary counterpart of hydraulic cylinders. They service several sectors, including aerospace, agribusiness, automotive, construction, forestry, manufacturing, maritime, military, oil & energy, and

waste management and recycling.

Gear and vane motors, generator motors, axial plunger motors, and radial piston motors are all types of hydraulic motors. They provide several speed ranges and fluid distribution systems. However, hydraulic motors typically include a reservoir, spinning equipment, and a pump. Collectively, these components implement the concept of hydraulics. It states that the majority of fluids cannot be compressed.

Consequently, if a fluid is put inside a closed system and force is applied to it, the force will ultimately push through the fluid to reach another location. The reservoir of hydraulic motors is where fluid is stored. This fluid is expelled into the system by the pump using hydraulic pressure. Hydraulic motors provide a substantial amount of power, particularly when compared to other motors of the same size.

Hydraulic Press

Hydraulic presses work by applying hydraulic pressure, which is also known as fluid pressure, to an object. Because they can apply so much force, hydraulic presses are much more effective than both mechanical presses and pneumatic pressures. They are very useful for clinching, molding, blanking, deep drawing, forging, punching, and forming metal in general. Furthermore, they can be used to compress food and other consumables. Also, they can help make ceramics, appliances, electrical parts, car parts, airplanes, and more.

There are a lot of different kinds of hydraulic presses that can be used. Common hydraulic press types include transfer presses, stamping presses, vacuum presses, platen presses, arbor presses, laminating presses, pneumatic presses, C-Frame presses, H-Frame presses, power presses, and press brakes.

Because hydraulic presses are used for so many heavy-duty tasks and have to withstand so much shear force, they are usually made of strong materials like

stainless steel. Also, they can be set up to work with either a single station or a group of stations. The single-station design only has one set of

tools , while the multi-station design has enough tools to do a wide range of press operations.

Hydraulic Pumps

Hydraulic pumps transform the energy provided by compressed fluids into mechanical energy that can be used. They are a crucial component of the majority of hydraulic systems and can be found in a variety of sectors.

Every hydraulic pump includes a reservoir, tubes or hoses, and a cylinder. The reservoir retains the stationary fluid. The tubes transport this fluid to the cylinder, which is the pump's main body. Two

valves, positioned at opposing ends of the cylinder, and at least one piston or gear system are contained inside the cylinder. One valve is known as the intake valve, while the other is known as the output valve.

The valves are responsible for allowing fluid into and out of the cylinder. The function of the piston is to compress or transport fluid. When the piston is retracted, the intake valve opens, generating a vacuum that sucks hydraulic fluid from the reservoir. When it returns to its initial position, the intake valve shuts, and pressure increases. The piston continually opens and closes the valves at variable speeds, accumulating pressure until the fluid is forced through the output valve. In this manner, the pump supplies the associated equipment with sufficient power and energy to move its intended load.

Hydraulic Seals

Seals are a component of the majority of

hydraulic systems, namely their moving components. Hydraulic seals often consist of a soft, flexible elastomer that provides them with superior water and air sealing qualities. They are ring-shaped and meant to prevent or minimize fluid leakage inside a hydraulic or pneumatic system. Among the elastomers that can be used to create hydraulic seals are polymers, plastics, rubber, (PTFE) Teflon, and polyurethane.

They work with industries like aerospace, agriculture, automotive, chemical processing, defense contracting, food processing, marine product manufacturing, medical and pharmaceutical product development, nuclear power, pulp and paper, and waste disposal.

Hydraulic seals have extensive uses. Hydraulic seals are found in brakes, clean rooms, conveyors, mixers, presses, valves, and test equipment. Furthermore, they are often found in hydraulic cylinders. Using oil, water, or another pressurized fluid, hydraulic cylinders are mechanical actuators that provide unidirectional force to agricultural and forestry vehicles,

construction equipment, and the like.

Hydraulic Valves

In hydraulic systems, hydraulic valves are used to control the flow and pressure of the fluid. They make sure that the fluid in these systems moves in a way that is safe, smooth, and under control. In particular, they can control the flow's direction, speed, pressure, and/or whether the fluid is moving or not. To do this, they open, close, or partially block passageways.

Hydraulic valves can be put into four main groups: flow control valves, pressure control valves, proportional control valves, and direction control valves. But there are many, many different kinds of valves. There are pressure relief valves, pressure regulators, sequence valves, shuttle valves, check valves, counterbalance valves, cartridge valves, and auxiliary valves. The oldest and most straightforward type of hydraulic valve is the check valve. They stop flow in one direction, or "check" it.

There are a lot of different sizes and ways to mount valves, like sub plate mounting, mounting in pipelines, and flanged mounting. You can also ask for your valves to meet ISO standards, but a good

manufacturer will do this on their own. Contact one or more of the excellent hydraulic equipment manufacturers below to find out more.

Hydraulic equipment manufacturer

In addition to providing clients with goods, several hydraulic companies in UAE also provide application engineering support and consultancy services so that customers have the finest help possible to complete their tasks effectively. This can involve assistance with system design,

construction, analysis, and project management, which helps ensure that hydraulic systems are ideally suited for dependable and smooth operation. For the most user-friendly hydraulic systems and components, it is always preferable to contact hydraulic companies in the UAE.