The process of steel fabrication in Dubai

Even though most

steel fabricators focus on the shape and build of the steel, an elite-quality object goes through many phases. Beginning with a design or rendering, the process concludes with a final, working component.

Designing a steel fabrication project

Design is the primary step in any project. Some businesses create their own designs. Most of the time, businesses bring a prototype. Before steel fabricators start making a lot of them, steel fabricators work with them to improve and test the design.

Computer Aided Design (CAD) and Computer Aided Manufacturing (CAM) are used by many steel fabricators in UAE. With CAD and CAM programs, steel fabricators can make a 3D model of an object before steel fabricators start making it out of steel.

Because a project can have many parts, this step helps make sure that the final product will work as expected. From the prototype or rendering, steel fabricators figure out the size and shape of each part steel fabricators need, as well as the type of steel and finishing techniques steel fabricators in UAE need.

Fabricating the part

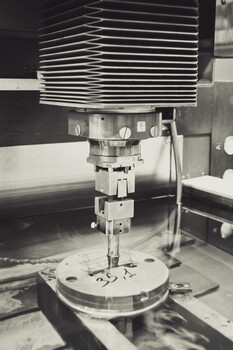

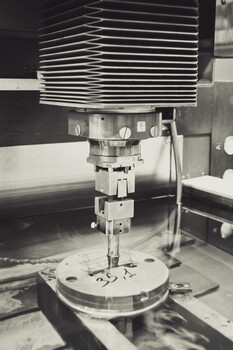

The real construction procedure is the second phase in steel manufacturing. During this step, steel fabricators cut and form each of the designed components. Shears, mills, lathes, and nibblers are some of the instruments used to produce steel.

Frequently, steel fabricators in UAE use CNC equipment to guarantee that each component is cut precisely to the design requirements. These technologies extract from a computer program the precise instructions and parameters required to make a work. The CNC machine is then loaded with this software.

The product is subsequently strengthened and made suitable for usage by finishing and assembly procedures. Finishing processes, such as grinding and deburring, assure the functionality and absence of extra material of the materials. Additionally, steels may be heat-treated or plated with zinc or comparable finishes to increase their strength.

Fabricators are also responsible for marking and printing items according to each project's requirements. This may contain dimensions, corporate logos, and other data.

Steel fabrication industries

Fabrication of steel has uses in several sectors. Due to the adaptability of its equipment and methods, it is used to manufacture components for sectors as diverse as agriculture, spas, military aircraft, and

automobiles.

Among the industrial uses of steel fabricators in UAE are:

- Parts for commercial and military aircraft.

- Agricultural equipment and accessories.

- Components of alternative energy for solar, wind, and geothermal constructions.

- Individual automobile and recreational vehicle components.

- Materials, equipment, and supplies for building projects.

- Food-safe equipment for food processing and packaging.

- Creation of consumer goods ranging from household appliances to automobile seats.

- Tools for military defense, communication devices, and vehicle parts.

- The use of fracking tanks and pumps.

Steel fabrication methods

Even the most basic items may need several processes and processing stages throughout the steel fabrication process, which goes beyond merely shaping steel. Most of the steel fabrication in UAE falls into three categories:

- Commercial: Commercial fabrication refers to the production of commercial goods. This category includes consumer-oriented products. Appliances and automobiles are both popular consumer goods that undergo commercial fabrication.

- Industrial: Industrial fabrication produces components for other machinery used in the production of consumer products. Numerous firms use industrial fabrication goods, such as ironworking machines and band saws.

- Structural: The term structural fabrication refers to steel working performed as part of the construction process. Typically, they are large-scale fabrication operations in which steel components for shops, factories, buildings, and skyscrapers are produced.

Within these categories, a steel fabrication company in UAE may include one or more of the following operations in the project:

- Laser cutting is used: A process that employs high-intensity laser beams to cut steel by melting, vaporizing, or igniting.

- Center less polishing and grinding: A finishing procedure for steel objects with precise tolerances that produces a uniform, smooth surface.

- CNC machining: A manufacturing technique for prototype and high-volume production that employs programmable computer software for maximum accuracy and efficiency.

- Forming and bending: Utilization of hydraulic machinery, CAD/CAM capabilities, and a variety of tools for bending and shaping materials according to requirements.

- The application of powder coating: An alternative to painting that offers a lasting, customized covering for steel items.

- Saw cutting:A technique of cutting that requires expert personnel and specific saw blades due to its extreme precision.

Steel fabrication and processes

Each business has distinct requirements, and each manufactured item has its own specs. The steel fabricating process may include a range of techniques for material reduction, shaping, and joining.

Reduction processes

Reduction procedures are among the most used methods for fabricating steel. These techniques remove portions of the steel to get the desired size and form.

Examples include:

- Shearing: Shearing is a typical way to cut steel parts to the desired size or form for aluminum, steel, stainless steel, brass, and bronze. Shearing is best suited for flat steel sheets.

- PunchingUsed to create holes in sheet or rolled steel, punching is steel fabricator suited for mass manufacturing.

- Blanking Used to generate steel work pieces for medium and high production workloads, blanking is most appropriate for sheet or strip steel and softer steels such as aluminum.

- NotchingUsed on a variety of steels to generate intricate cuts and angles that are not feasible with typical shearing operations.

- The application of powder coating: An alternative to painting that offers a lasting, customized covering for steel items.

- Saw cutting:A technique of cutting that requires expert personnel and specific saw blades due to its extreme precision.

Shaping processes

Occasionally, steel must be sculpted rather than merely sliced. There are a variety of steel-forming techniques available. During fabrication, steel is often chopped before being formed.

Examples of shaping include:

- Stamping: Stamping generates one or more elevated steel portions. Stamping may refer to progressive die drawing, shallow stamping, or deep stamping. This process is often used to manufacture medium to large quantities of components.

- Folding: During the manufacturing process, angles are created in sheet steel by the process of folding.

Other processes

Several more procedures used in the steel production procedure link separate sheets of material or form big blocks of steel, including:

- Welding:it's one of the most frequent methods for joining steel objects. A proficient welder can expand sheet steel and attach it using a variety of joints.

- Machining:Machining, which is frequently seen as a distinct business from steel fabrication in UAE, plays a crucial part in the process. Nevertheless, many steel fabricators in UAE do machining.

How to select a steel fabrication company in UAE

Finding the appropriate steel fabrication company in UAE for a project may be difficult. Asking a few questions beforehand might aid in locating the ideal fabricator. Before deciding, there are five questions you should ask a steel fabrication company in UAE.

Is the company capable of accomplishing your project?

One of the first things to ask when selecting a steel fabricator is if the firm has the capacity to handle your job. There are several steel fabricators in operation. Some professionals specialize in just one industry. Others provide an array of services.

Look for a business that specializes in precision fabrication if your fabrication job is intricate or has a very little margin for mistakes. If a steel fabricator services this industry, it is probable that they possess the necessary abilities and expertise for additional precise work.

Inquire about the company's average project size. If a fabricator specialized in custom-made items, it may not have the ability to swiftly fulfill bigger requests.

What in-house services does the steel fabricator provide?

It is stressful to hire a fabricator just to discover that they outsource part of their services. Unfortunately, many fabricators outsource portions of the design or finishing processes.

Before choosing a steel fabricator in UAE, inquire about the services they provide and if they outsource any. Do the personnel manage all phases of construction and fabrication? What is their level of expertise?

During the design phase, it might also be beneficial to seek assistance. Can you collaborate with the company's engineers to alter your design if necessary?

Some clients provide us with a comprehensive computer rendering and working prototype. Others want to test and adjust designs before mass production. Our in-house engineering staff may collaborate with these clients to revise designs and provide guidance on how to acquire the higher-quality component.

How many employees does the business have and what is their experience?

For a steel fabrication project to be successful, it is essential that the team be comprised of knowledgeable individuals. Inquire of prospective partners about their team size and expertise in the sector.

Fabricators of steel propose seeking out companies with trained engineers and welders on staff. Certification shows that a member of staff has the necessary knowledge and skills to do a project well.

What is included in the project bidding?

When searching for a steel fabricator in UAE, it is usual to get many offers, but not all bids include the same information. When comparing quotes from fabricators, it is essential to comprehend precisely what is included in each proposal.

Among the factors to consider in a bid are:

- The services provided by the steel fabrication company in Dubai.

- Whether the proposal includes revisions.

- An estimate of the duration of the project.

- The price of raw resources./li>

- Who is accountable for the procurement of materials?

Additionally, it might be useful to inquire if the steel fabrication company in UAE has raised their offer and, if so, by how much. Most project plans contain padding to accommodate potential issues, such as redesigning a portion of the plan or obtaining resources.

Is the company capable of sourcing materials and completing jobs on time?

The UAE is home to some of the top steel fabrication companies in Dubai. If you will be creating components for use in the UAE, choosing a UAE-based steel fabricator may make a significant difference. It will minimize delivery time and expenses as well as material procurement issues.

Especially if you're creating big or heavy pieces, you may want to determine whether the fabricator has a warehouse or factory close to your business.

The location and connections of a company's suppliers are also essential. If a store has a positive connection with its suppliers and pays its bills on time, it will have an easier time sourcing supplies. This is especially essential if your components need uncommon steel.

Steel fabrication companies in UAE

Contact these steel fabrication companies in UAE for all your needs in steel fabrication in UAE through our

business directory.There are many steel fabrication companies in Dubai that make precise pieces of steel. Their skilled engineers and fabricators make parts for many different types of enterprises. With their wide range of services and value-added processing, they can handle all your custom steel fabrication needs in one place.